Mastering In-Mold Decorations: Approaches, Patterns, and Ideal Practices for Ideal Outcomes

In the world of production, the art of in-mold decors stands as a pivotal aspect of product design and production. In-Mold Decorations. By delving into the techniques, trends, and best practices that underpin successful in-mold decoration processes, companies can unlock a realm of possibilities that not just boost the visual attraction of their items however likewise enhance production effectiveness and reinforce consumer engagement.

Material Option

Product choice is a crucial facet of mastering in-mold decors, as it directly influences the quality and durability of the final item. When choosing products for in-mold decors, it is necessary to consider aspects such as compatibility with the molding process, the preferred visual outcome, and the ecological conditions the product will certainly face.

Additionally, the selected material must have good bond residential or commercial properties to make sure that the decoration adheres securely to the substratum during the molding process. Bond in between the decor and the product is essential for stopping delamination and making certain lasting visual charm. In addition, materials with high warm resistance are liked for in-mold decorations, specifically for products that will be subjected to raised temperature levels throughout their lifecycle. By carefully choosing the proper product for in-mold decorations, producers can enhance the general high quality and durability of their products, fulfilling the expectations of both end-users and customers.

Layout Advancement

A necessary variable in progressing the field of in-mold decorations is the continuous expedition and execution of style development techniques. Layout technology plays a critical function in improving the aesthetic allure, performance, and total quality of items produced using in-mold decor procedures. By integrating innovative layout aspects, manufacturers can separate their products in the market, bring in consumers, and stay in advance of competitors.

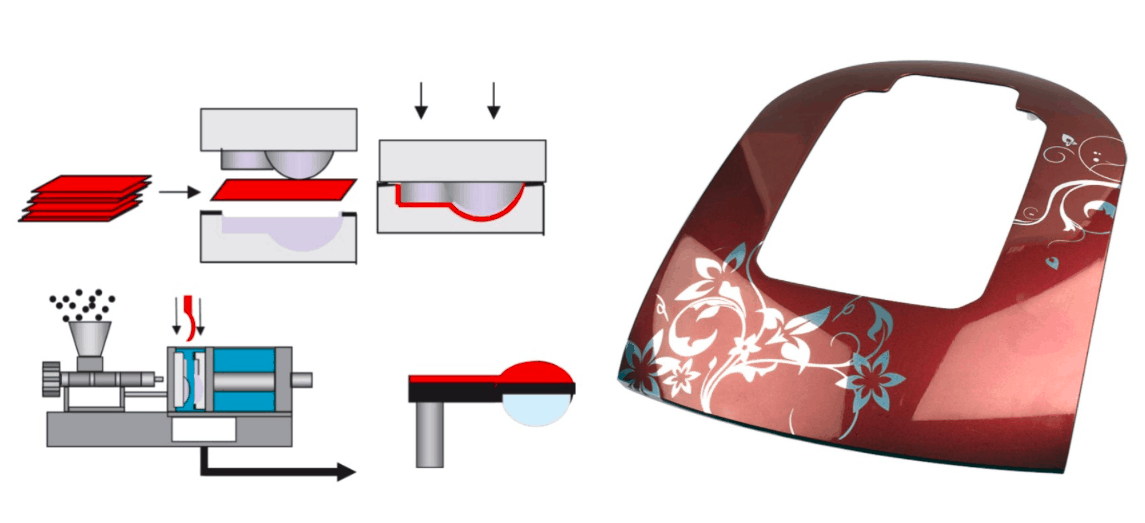

Among the essential aspects of style development in in-mold decors is the combination of intricate patterns, appearances, and graphics that were previously testing to accomplish with typical design methods. Advanced innovations such as 3D printing and digital style tools allow designers to produce facility and in-depth layouts that can be perfectly moved onto molded components. Additionally, making use of vibrant colors, metal finishes, and unique results like gloss or matte textures can better elevate the aesthetic charm of in-mold enhanced products.

Moreover, layout development expands beyond looks to encompass practical enhancements such as ergonomic forms, integrated features, and customizable elements that cater to specific user needs. By accepting layout advancement, suppliers can open brand-new opportunities for creative thinking, item, and personalization differentiation in the competitive landscape of in-mold decors.

Manufacturing Performance

Effective production procedures are vital for converting the cutting-edge styles created in the field of in-mold designs into premium completed products that fulfill market demands and customer assumptions. In the realm of in-mold decorations, manufacturing efficiency incorporates numerous crucial aspects that add to the overall success of the production process.

Automation not only accelerates the manufacturing procedure however likewise enhances precision and repeatability, leading to an extra consistent and premium end item. Overall, an alternative method to manufacturing effectiveness is vital in optimizing the possibility of in-mold decoration strategies and accomplishing optimum results in the competitive market landscape.

High Quality Control Procedures

What are the essential strategies for ensuring rigorous high quality control actions look here in the world of in-mold designs? Quality control actions are critical in in-mold i thought about this design procedures to make certain the manufacturing of remarkable and premium finished items.

Using advanced innovations such as automatic examination systems can additionally improve the top quality control procedure by giving accurate and trusted data for evaluation. These systems can identify blemishes that might be missed out on by manual evaluations, thus enhancing general product high quality and consistency.

Routine training and development programs for workers associated with the in-mold decoration procedure can additionally add to keeping high-grade standards. By informing personnel on best practices, high quality expectations, and the value of interest to detail, companies can foster a society of top quality awareness throughout the organization.

Customer Allure

To improve the marketability of in-mold decor items, understanding and providing to customer preferences play an essential role in determining their allure and success. Consumer allure in in-mold designs is influenced by various elements, consisting of style aesthetic appeals, color options, toughness, and overall functionality. Consumers are progressively seeking customized and unique items that reflect their originality and style. As a result, using customization alternatives such as tailored designs, color variants, and textural elements can dramatically improve the appeal of in-mold decor products.

Verdict

In-mold decorations offer a flexible and effective means to boost item visual appeals. By thoroughly choosing products, accepting ingenious styles, maximizing manufacturing processes, applying high quality control measures, and prioritizing consumer appeal, manufacturers can accomplish ideal outcomes. It is vital for firms to consistently adjust and boost click this site their methods to remain competitive on the market. In-Mold Decorations. Grasping in-mold decorations requires a holistic approach that takes into consideration all facets of the production process to ensure success.

In the world of manufacturing, the art of in-mold decors stands as an essential aspect of item style and production. Style development plays a crucial duty in improving the visual charm, functionality, and general quality of items manufactured making use of in-mold design procedures.One of the crucial aspects of style innovation in in-mold decors is the integration of complex patterns, appearances, and graphics that were previously testing to achieve with standard decoration techniques.Efficient production procedures are vital for converting the ingenious layouts developed in the area of in-mold decors into high-grade finished items that fulfill market demands and consumer assumptions. Offering personalization alternatives such as customized styles, shade variations, and textural aspects can dramatically enhance the appeal of in-mold design items.